"Smart" control cabinet design from the outset

Weikl Automatisierungstechnik puts it trust in the ECAD platform

Although the Weikl group of companies in Bodenmais was well prepared to take the step: Four years ago it virtually went from 0 to 100 in the new automation business line. The EPLAN Platform was used from the outset. Consistent design with the integration of production enable a high degree of flexibility and automation. Just four years after its establishment, the company has achieved a good market positioning with expansion already being planned.

The Weikl group of companies in Bodenmais/Bavarian Forest is already experienced in developing new lines of business. Founded in 1976 as an electrical company for hotel and industrial engineering, it added civil engineering as a second line of business two years later. In the 1980s, Franz Weikl sen. single mindedly expanded electrical planning and automation for building services engineering and established Weikl GmbH & Co. KG as a specialist for electrical and safety engineering. This company undertakes challenging projects throughout Bavaria and beyond ranging from hotels, clinics, thermal spas and universities through to production plants.

Well prepared: Getting started in automation

By 2013, the company already had 125 employees and were installing the first in-house produced, low-voltage main distribution boards (up to 5000 A). With the founding of Weikl Automatisierungstechnik GmbH in 2015, another new business line was opened up: the development and manufacture of controllers and energy distributors for smart buildings and industrial machines.

Franz Weikl jun. had prepared well for this step: a spacious new building for the company headquarters, with 1200 m2 floorspace for administration and 2500 m2 for production, as well as the recruitment of an experienced workforce in sales, electrical design and control cabinet engineering.

ECAD: Integration from planning to production

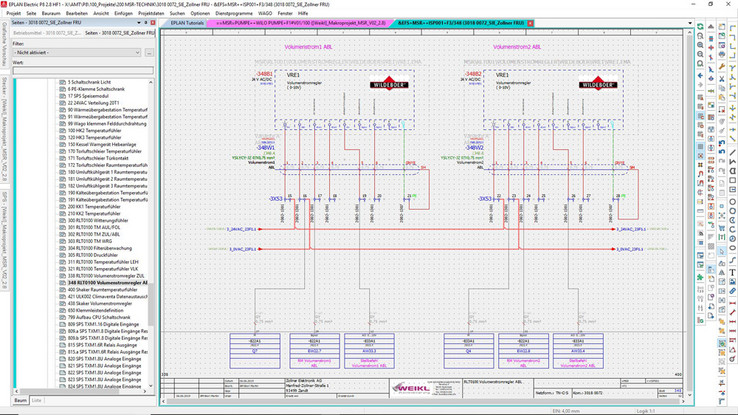

At the CAD level, Weikl implemented from the outset a platform for integrated planning, design and production. Franz Weikl: "We work with the EPLAN Platform and aim to avoid duplication as well as to enable the data we generate during the design phase to be used also in production". That this aim has been achieved is evident in the design department, which works in direct visual contact with control cabinet engineering.

Getting started with EPLAN Preplanning

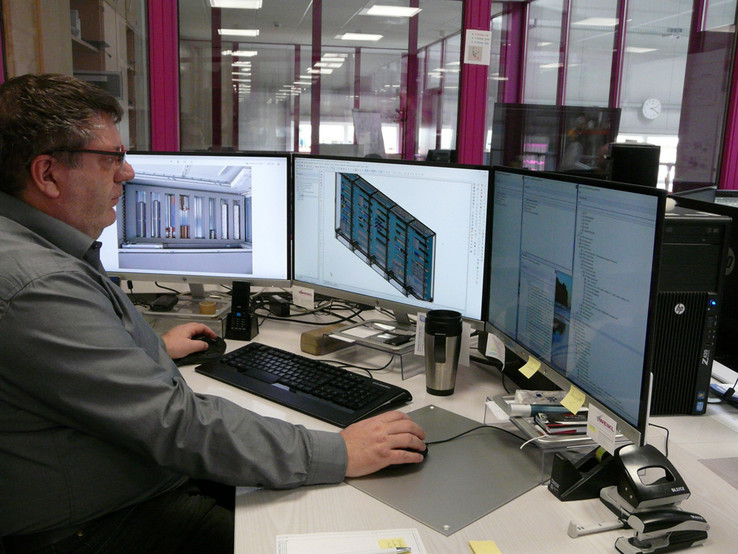

The design engineers' workstations are equipped with a three-monitor system. They begin their task using EPLAN Preplanning and select functions and modules that relate to each other. If the selected functions and modules are stored in the system, the schematic can then be largely created automatically. Franz Weikl: "Because we started at ‘zero’, colleagues initially had to enrich the Preplanning database and input the components and functions. In return, we now benefit from considerably accelerated processes right from the design phase". The principle of "design instead of drawing" applies, with the data being processed directly in detailed planning. This means saving time and having smart electrical engineering.

Control cabinet design: In three dimensions

When designing the control cabinets and power distribution systems, the Weikl automation engineers work with EPLAN Pro Panel and thus in the third dimension. Production Manager Christian Eberl: "The 3D mounting layout makes planning much easier because the control cabinets of many of our customers have limited space. Functions such as collision monitoring can be used to optimise layouts, and the 3D views are a good basis for discussing the design with the customer". In addition, the data can also be used for calculating thermal properties and thus for dimensioning the (usually passive) cooling systems. The designers benefit from the fact that Weikl works 98% of the time with Rittal enclosures, unless the customer requests otherwise. Data for Rittal enclosures is already recorded in the EPLAN Data Portal and can be stored centrally in EPLAN's parts management.

Mechanical manufacturing with a direct CAD connection

Weikl also uses automation in the mechanical processing of control cabinets, using data from EPLAN Pro Panel. Christian Eberl: "A CNC machining centre with an automatic tool changer uses the transferred EPLAN data for drilling and milling, and works through the tasks. All the operator needs to do is clamp the part and run the program". Drilling patterns are created automatically.

Monitor-guided wiring using EPLAN Smart Wiring

Wiring is generally the most time-consuming step in control cabinet engineering and is supported on the shop floor by the browser-based assistance system EPLAN Smart Wiring. A monitor visualises the wiring and displays the next step, with source and destination descriptions, cross-sections, colours and routing tracks. The 3D representations from EPLAN Pro Panel act as a basis for the data. When a wire has been routed, the technician confirms the task, and the next wire to be routed is then displayed.

Only one of the wiring workstations is currently equipped with EPLAN Smart Wiring. Christian Eberl: "We still work manually and paper-based at the other workstations. But soon we’ll be using EPLAN Smart Wiring 100%, and purchasing a wiring robot as an additional step."

Summary: End-to-end automation

In its electrical engineering, Weikl has implemented consistent planning and deep integration into the various areas of assembly and production that are now largely automated. This was exactly the aim when the decision was made in favour of the EPLAN Platform in 2015. Franz Weikl: ">Our staff should be doing challenging rather than repetitive tasks. This also makes us faster and more flexible". And that's another goal that has good reason to be met: "In building automation, we have around a 6–8 months lead time because building technology is installed late in the construction process. In our industrial line of business, i.e. in automation engineering, speed is often required. Speed enables us to stand out from the competition, as does the high quality of planning that we offer thanks to the integrated ECAD platform"

Well qualified for challenging tasks

The idea of entering the automation technology market with high initial investments may seem at first daring. But it was a well prepared idea which quickly brought success. For example, staff in the new business area have planned and installed complete automation systems, including the I&C engineering, for several companies in the glass industry – an industry which is traditionally strongly represented in the Bavarian Forest. For a manufacturer of sanitary ceramics, Weikl Automatisierungstechnik also planned and programmed the complex process technology for mixing and processing the company’s base materials. Within just four years, the company has therefore become well established. Franz Weikl Jr: "We are proof that specialists exist in the Bavarian Forest for highly demanding automation requirements, and we are now having success far beyond the region". Such entrepreneurial spirit has also been acknowledged by the experts: Weikl has been nominated for Germany's most important business award, the "Grand Prix Mittelstand".

Designers use a three-monitor system and consistently work with the EPLAN Platform, starting from Preplanning and Pro Panel through to Smart Wiring.

When designing the control cabinets and power distribution systems, the Weikl automation engineers work with EPLAN Pro Panel and therefore in the third di-mension.